In the fast-paced world of manufacturing, efficiency is key, and the Pallet Conveyor System stands out as a technological marvel, reshaping the landscape of automated material handling. This innovative system brings forth a plethora of features and advantages, setting it apart from traditional conveyors and providing an unmatched solution for modern production facilities.

1. Precision and Customization:

Tailored Designs: Pallet conveyors offer a level of precision and customization that traditional conveyors struggle to match. Manufacturers can choose from various designs, such as flat belts, Roller chains, and plastic chains, tailoring the system to meet the specific needs of their production lines.

Adaptable Handling: The system accommodates a diverse range of products, from trays and batteries to flat belts and beyond. Its adaptability ensures seamless integration into different industries, from automotive assembly lines to household product manufacturing.

2. Automated Efficiency:

Smart Automation: Pallet Conveyor Systems are at the forefront of automation, utilizing advanced technologies like Conveyor Positioning, motor control, and rotation. These automated features optimize material flow, reducing manual interventions and enhancing overall production efficiency.

Production Line Integration: Designed for assembly line efficiency, these systems facilitate smooth transitions between manufacturing stages. From automated tray handling to precise positioning, every aspect is meticulously engineered for a seamless production experience.

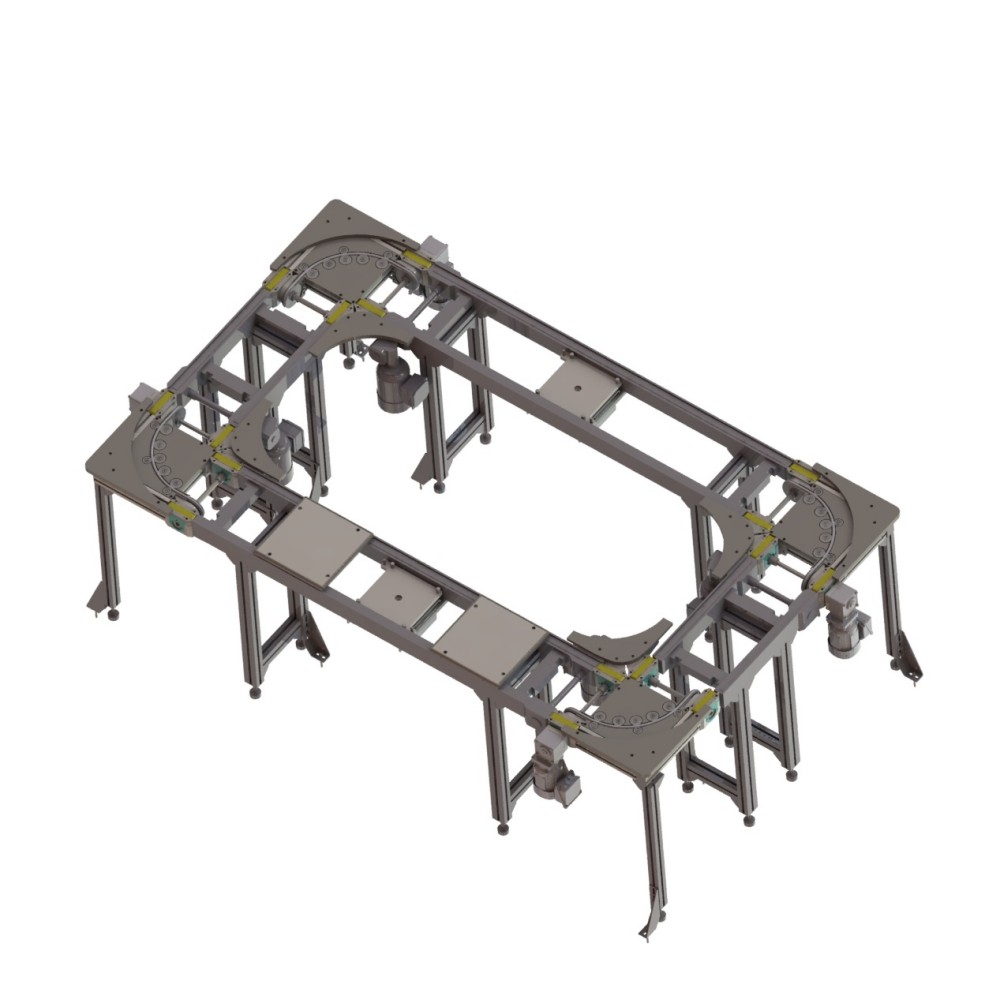

3. Modular and Scalable Solutions:

Modular Design: The modular nature of Pallet Conveyor Systems allows for easy expansion and adaptation to evolving production needs. Manufacturers can scale their operations effortlessly by adding or modifying Conveyor segments, ensuring a future-proof solution.

Space Optimization: With a compact and modular design, these conveyors optimize floor space utilization. The ability to navigate curves, handle different pallet types, and transport materials vertically makes them an ideal choice for confined spaces.

4. Sustainable Material Handling:

Energy-Efficient Solutions: Pallet conveyors prioritize energy efficiency, contributing to cost savings and sustainable manufacturing practices. They incorporate advanced motor control and timing belt technologies to minimize energy consumption.

Environmentally Friendly Materials: Vitrans, as a leading manufacturer, focuses on sustainability by using recyclable materials in the construction of their conveyor systems. This commitment to environmental responsibility ensures a reduced ecological impact.

In essence, the Pallet Conveyor System redefines automated material handling, offering a perfect blend of precision, automation, and sustainability. As the industry evolves, these systems emerge as the cornerstone for efficient and future-ready manufacturing processes.”